The Ultimate Guide to Electrical Safety for Tradespeople: Essential Practices for a Secure Workplace

Electrical safety is paramount for tradespeople who routinely engage with high-risk environments and equipment. Whether you are an experienced electrician or a tradesperson whose work occasionally involves handling electrical systems, it’s crucial to have a profound understanding of the dangers electricity poses and the safety measures to mitigate these risks. Being equipped with the right knowledge and tools can protect against electric shocks, burns, and other serious injuries, preserving not only your wellbeing but also ensuring the safety of colleagues and clients.

To maintain a safe working environment, adherence to safety protocols and best practices is essential. This includes conducting thorough risk assessments, adhering to updated regulations, and utilising appropriate personal protective equipment. By understanding the specific hazards associated with electrical work, you can implement strategies that address potential dangers before they escalate into incidents. For tradespeople, recognising the unique challenges faced in their work settings is key to tailoring safety measures effectively.

Of course this guide does not replace the need for courses and qualifications to ensure that you are approaching on-site safety in the correct manner, but hopefully it gives you a good place to start.

Key Takeaways

- Understanding electrical safety regulations is essential for risk prevention.

- Regular risk assessments are crucial in identifying and managing potential hazards.

- Adoption of best practices and proper PPE is vital for tradespeople’s safety.

Understanding Electrical Safety

Ensuring your safety when working with electricity is paramount. This section will provide you with a practical understanding of electrical safety, from the fundamentals of electricity to common hazards and safety regulations you must adhere to.

Fundamentals of Electricity

Electricity is a form of energy that flows through conductors to power devices and equipment. You should be familiar with basic electrical concepts such as voltage, current, and resistance, collectively defined by Ohm’s Law:

- Voltage (V): The potential difference that pushes the electric current through a circuit.

- Current (I): The flow of electric charge measured in amperes (A).

- Resistance (R): The opposition to the flow of current, measured in ohms (Ω).

Always remember that high voltage can cause severe injuries or death, and even a small current could be lethal under certain conditions.

Common Electrical Hazards

You’ll frequently encounter various electrical risks on the job. Being aware of these risks is crucial:

- Electric Shock: Accidental contact with live parts can cause muscle contractions or a heart attack.

- Arc Flash/Blast: A sudden discharge of electricity through air, resulting in an explosive release of energy, which can cause burns.

- Fire: Faulty wiring or overloaded circuits can cause electrical fires.

Preventative Measures:

- Use insulated tools and wear rubber-soled boots.

- Maintain a safe distance from live electrical parts.

- Regularly inspect electrical equipment for damage.

Electrical Safety Regulations

In the UK, the Electricity at Work Regulations 1989 outlines the responsibilities of both employers and employees to maintain safety standards while handling electrical systems. Key components of these regulations include:

- Risk Assessment: Identify potential electrical hazards before commencing work.

- Maintenance: Keep electrical systems and protective equipment in good working order.

- Training and Competence: Ensure that individuals working with electricity have adequate training.

Your Responsibilities:

- Follow all relevant safety procedures and guidelines.

- Report any electrical hazards to your supervisor.

- Never work on live systems unless absolutely necessary and you are qualified to do so.

Staying informed and vigilant is your best defence against electrical accidents. By understanding these key aspects of electrical safety, you will be better equipped to work safely and efficiently in your trade.

Risk Assessment and Management

Before you begin any electrical work, it’s essential to conduct a thorough risk assessment, implement effective control measures, and follow safe isolation procedures. This approach minimises the risk of injury or damage during electrical tasks.

Conducting a Risk Assessment

When conducting a risk assessment, initially you must identify potential hazards associated with the electric work. Evaluate the risks by considering the severity and likelihood of an adverse event occurring. To document your findings, use a risk assessment table like the one below:

| Hazard | Persons at Risk | Likelihood | Severity | Overall Risk |

| Exposed live wires | Electricians, other tradespeople | High | High | High |

| Faulty equipment | Tradespeople, clients | Medium | High | High |

| Overloaded circuits | All site personnel | Low | High | Medium |

Once assessed, create a plan to manage these risks, incorporating suggestions and regulations provided by the Health and Safety Executive (HSE). Make sure this plan is accessible and understood by all team members.

Implementing Control Measures

After identifying the risks, you must implement control measures to mitigate them. Prioritise the hazards and tackle those with the highest risk first. Control measures can include:

- PPE: Appropriate personal protective equipment such as gloves, goggles, and fire-retardant clothing.

- Training: Ensure that you and your team have up-to-date knowledge on electrical safety standards.

- Equipment checks: Regularly inspect and maintain your tools and machinery to ensure they’re in safe working condition.

It’s crucial to review and update your control measures periodically, as working environments and legal requirements can change.

Safe Isolation Procedures

To manage risks effectively, safe isolation is a key procedure every electrician must implement. Below is a checklist for safe isolation:

- Notify: Inform all affected parties that you’re about to isolate power supplies.

- Identify: Correctly identify the circuits or equipment set to be isolated.

- Isolate: Switch off the power supply using an approved isolation device.

- Lock Out: Apply lockout devices to prevent accidental re-energising.

- Verify: Use appropriate test equipment to verify the absence of voltage.

- Earthing: If required, apply earthing devices to discharge residual energy.

Following these steps ensures that the work area is completely safe from unintended electrical power, protecting you and others from electrical hazards during work activities.

Protective Measures and Best Practices

Adherence to protective measures and best practices is essential in mitigating risks associated with electrical work. Below are critical strategies for ensuring safety.

Personal Protective Equipment (PPE)

You must wear appropriate PPE to shield yourself from hazards such as electric shock, arc flash, and fires. Key items include:

- Insulated Gloves: Use gloves rated for the voltage you are working with to protect against shocks and burns.

- Protective Eyewear: Protect your eyes from flying debris and arc flash incidents with safety glasses or face shields.

- Flame-Resistant Clothing: Reduce the risk of injury from fires and arc flashes with flame-retardant garments.

Remember that damaged or improperly used PPE will not provide adequate protection.

Preventive Maintenance and Inspections

Regular checks and maintenance are vital in preventing electrical accidents. Your routine should include:

- Tool and Equipment Inspections: Before use, inspect electrical tools and equipment for damage or wear. Test for proper operation.

- Environmental Inspections: Ensure the workspace is free from hazards such as damp conditions that may increase the risk of electric shock.

- Scheduled Testing: Perform regular testing of electrical systems and protective devices to ensure they are functioning correctly and safely.

Documentation of all maintenance and inspections should be kept up-to-date.

Responding to Accidents and Injuries

In the event of an accident, your response can significantly affect the outcome. Be prepared to:

- Assess the Situation: Quickly and safely determine the nature of the accident, such as shocks or burns.

- Emergency Procedures: Initiate appropriate emergency responses, including shutting down power sources and calling emergency services.

- First Aid: Administer first aid where qualified, focusing on treating burns or shock while waiting for professional medical help.

Regularly review and practice your emergency response plan to ensure you can act swiftly when necessary.

Special Considerations for Tradespeople

In your trade, being keenly aware of how to navigate the risks associated with electricity is crucial. This section provides you with targeted guidance to manage these risks effectively.

Dealing with Overhead Power Lines

You must maintain a safe distance from overhead power lines at all times. Construction industries often operate in close proximity to these hazards, so knowing the regulations is vital. The Electricity at Work Regulations 1989 stipulate that:

- No work should be carried out under or near overhead power lines unless absolutely necessary.

- Where work must be done, then safe working distances must be established and followed rigorously.

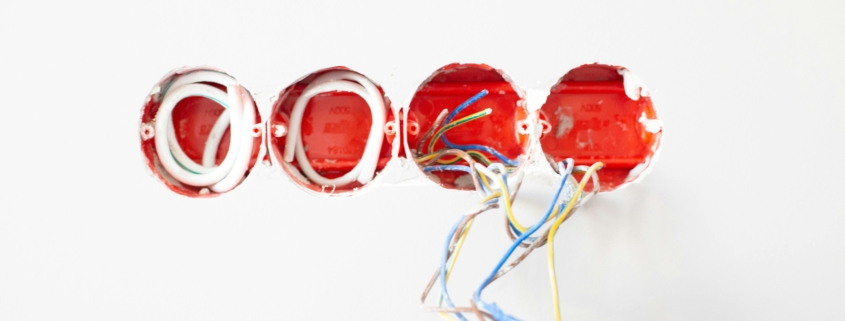

Equipment and Tool Safety for Installers

Your electrical equipment and tools define your efficiency and safety on the job. As an installer:

- Regularly inspect tools for damage and wear.

- Use RCD (Residual Current Device) protected power supplies to help prevent electric shock.

- The below tables gives some examples of damage and wear to check for.

Table: Tool Inspection Checklist

| Frequency | Check for |

| Before use | Cuts, fraying, and general wear in cables |

| Weekly | Proper grounding and damage to plugs |

| Monthly | Tool casing damage and operational functionality |

Training and Industry Specific Guidance

Your training should include specific instruction in line with HSE guidelines. It’s not merely about preventing fatalities or serious injuries from electric shock; it’s about fostering a culture of safety.

Consider the following recommendations for your continuous professional development:

- Participate in certified electrical safety training courses.

- Stay updated with industry-specific guidance and best practices provided by HSE.

Avoiding fatalities and reducing death rates in the construction industry and other industries with a high risk of electrical incidents is your responsibility. Your adherence to these guidelines could be lifesaving.